Top Tips for Choosing the Right Forklift Battery for Your Needs

Choosing the right forklift battery is crucial for optimizing operational efficiency and ensuring the longevity of your material handling equipment. With the market for forklift batteries expected to reach $2.65 billion by 2026, understanding the various options available is more important than ever. A well-chosen forklift battery not only enhances productivity but also contributes significantly to the overall cost-effectiveness of warehouse operations. As noted by industry expert Dr. Emily Chen, “The right forklift battery can reduce operational costs by up to 30% by improving energy efficiency and reducing maintenance needs.”

When selecting a forklift battery, factors such as capacity, lifecycle, and charging capabilities come into play. Reports suggest that approximately 60% of battery-related downtime is due to improper battery selection or maintenance, highlighting the importance of making informed decisions. Furthermore, advanced technologies in forklift battery designs, such as lithium-ion and lead-acid, offer a range of benefits tailored to specific industrial applications. As businesses continue to seek ways to enhance their logistics and supply chain operations, understanding these complexities will empower decision-makers to invest wisely in forklift battery solutions that align with their operational needs.

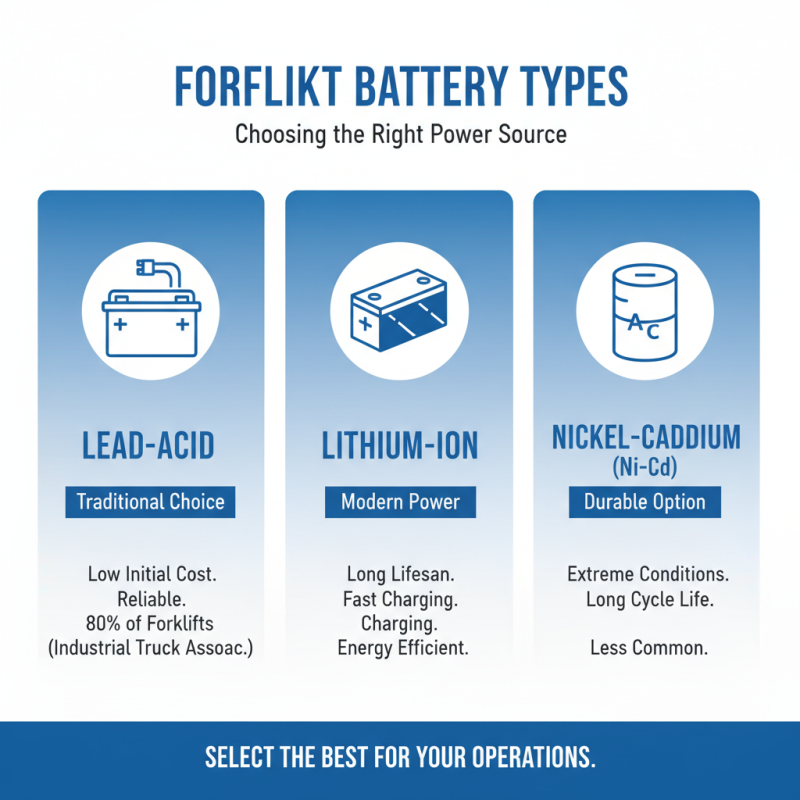

Understanding Different Types of Forklift Batteries Available in the Market

When it comes to selecting the right forklift battery, it’s essential to understand the different types available in the market. The most common types are lead-acid batteries, lithium-ion batteries, and nickel-cadmium batteries. Lead-acid batteries are the traditional choice, favored for their low initial cost and robust performance in various conditions. According to a report by the Industrial Truck Association, approximately 80% of forklifts in use today are powered by lead-acid batteries, reflecting their widespread reliability and effectiveness in warehouses and manufacturing industries.

On the other hand, lithium-ion batteries have been gaining traction thanks to their advantages in energy density and longevity. With a higher upfront investment, these batteries typically offer longer lifespans and faster charging times, which can lead to decreased operational costs in the long run. A study from the Battery University indicates that lithium-ion batteries can last up to three times longer than their lead-acid counterparts, making them an attractive option for businesses focused on efficiency and sustainability. Additionally, they require less maintenance—no need for regular water refills and equalization charging—thus allowing companies to allocate their resources more effectively.

Lastly, nickel-cadmium batteries, while not as common today, still serve niche applications due to their robustness and ability to perform in extreme temperatures. Though they face criticism for being less environmentally friendly, they excel in certain scenarios where durability and reliability are paramount. Understanding the characteristics and performance of each battery type is crucial for making an informed decision that aligns with the operational needs and budget constraints of your forklift fleet.

Evaluating Battery Capacity and Voltage Requirements for Your Forklift

When selecting the right forklift battery, evaluating the battery capacity and voltage requirements is crucial to ensure optimal performance and longevity. Battery capacity, usually measured in amp-hours (Ah), determines how long the forklift can operate before needing a recharge. Understanding your operational needs—whether you're handling light or heavy loads—will help you select a battery that can sustain your daily activities without frequent downtime. Consider the average cycle time and the total hours of operation to match the capacity effectively with your forklift's demands.

Voltage requirements are equally important as they directly influence the forklift's lifting and operational power. Most forklifts operate on standard voltages such as 6V, 12V, or 48V, and it's essential to choose a battery that matches the voltage specifications of your forklift. This ensures not only compatibility but also efficiency in performance. If the voltage requirement is not met, it can lead to reduced power output and potential damage to the forklift's electrical system. Therefore, thorough evaluation of both battery capacity and voltage will ensure that your forklift operates smoothly, maximizing productivity while minimizing maintenance issues.

Top Tips for Choosing the Right Forklift Battery for Your Needs

| Battery Type | Voltage (V) | Capacity (Ah) | Average Lifespan (Years) | Maintenance |

|---|---|---|---|---|

| Lead-Acid | 12 | 150 | 5-7 | Requires regular watering |

| Lithium-ion | 24 | 200 | 8-10 | Low maintenance |

| Gel Cell | 12 | 100 | 4-5 | No maintenance required |

| AGM | 12 | 120 | 5-7 | Sealed, low maintenance |

Assessing the Lifespan and Maintenance Needs of Forklift Batteries

When it comes to choosing the right forklift battery, assessing the lifespan and maintenance needs is essential for optimal performance and cost-effectiveness. Forklift batteries are typically designed for multiple charge cycles, but their longevity depends on various factors such as usage patterns and maintenance routines. Generally, a well-maintained battery can last between 5 to 7 years. Regularly checking fluid levels, inspecting terminals for corrosion, and cleaning the battery surface can significantly enhance its lifespan. Implementing a proper charging routine, ensuring that the battery is not over-discharged, will also prolong its usability.

Here are some essential tips for maintaining your forklift battery: First, establish a routine inspection schedule to monitor the battery's condition, paying close attention to any signs of wear or damage. Second, always clean the battery terminals to ensure good electrical connections, as dirty terminals can lead to reduced efficiency. Lastly, when recharging, do so at appropriate intervals rather than waiting until the battery is fully drained; this practice will not only maximize battery life but also improve performance reliability during operations. By following these maintenance strategies, businesses can ensure that their forklift batteries remain robust and efficient, enhancing their overall productivity.

Considering Environmental Factors Affecting Battery Performance

When selecting the right forklift battery, considering environmental factors is crucial for optimal performance and longevity. Temperature fluctuations, for instance, can significantly impact battery efficiency. In colder environments, batteries may experience reduced capacity and longer charging times, while excessive heat can accelerate degradation, leading to shorter lifespan and potential operational failures. Therefore, it's essential to assess the operating conditions of your workplace and choose a battery that can withstand these environmental extremes.

Another important factor to consider is humidity. High humidity can lead to corrosion and reduce battery life. Conversely, very dry conditions might increase the likelihood of static discharge issues. It’s advisable to evaluate the humidity levels in your facility and ensure that the battery is well-maintained to prevent such issues. Additionally, the presence of dust and chemicals in the work environment can also affect battery performance. Selecting a battery designed for harsh conditions or utilizing protective housing can mitigate these risks and contribute to more reliable forklift operations.

Budgeting for Your Forklift Battery Purchase and Long-Term Costs

When budgeting for a forklift battery purchase, it’s crucial to consider both the initial costs and the long-term expenses associated with battery maintenance and replacement. Start by evaluating the type of battery that best suits your operational needs, as different technologies such as lead-acid or lithium-ion can significantly affect upfront costs.

While lead-acid batteries may be less expensive upfront, they typically require more maintenance and have a shorter lifespan compared to lithium-ion batteries, which, despite being a bigger investment initially, may offer lower total cost of ownership over time.

Additionally, factor in the costs of routine maintenance and potential repairs. Regular maintenance can prevent unexpected expenses that arise from battery deterioration or failure. Consider also the charging infrastructure and potential energy costs; some batteries might require different charging equipment, which can add to your overall expense. Anticipating these variables can help you make a more informed decision while ensuring that you align your forklift battery choice with your financial strategy and operational efficiency for years to come.

Related Posts

-

How Best Forklift Battery Optimizes Warehouse Efficiency with Real World Applications

-

7 Reasons Why the Lithium Iron Phosphate Battery is the Best Choice for Your Energy Needs

-

How to Select the Right Lithium Ion Battery Cell for Your Energy Needs

-

China Leading the Way in Manufacturing the Best Miniature Circuit Breakers for Global Buyers

-

Unlocking the Power: How Lithium RV Batteries Outperform Lead-Acid with 30% More Efficiency and Lifespan

-

Top 10 Benefits of Using Lithium Batteries for Your Devices in 2023