7 Essential Tips for Choosing the Right Vacuum Circuit Breaker

When it comes to ensuring the safety and reliability of electrical systems, understanding the intricacies of Vacuum Circuit Breakers (VCBs) is vital. As a key component in modern electrical infrastructure, these devices provide efficient protection against overloads and short circuits while maintaining operational continuity. However, the selection process for the right Vacuum Circuit Breaker can be daunting due to the variety of models and specifications available. Factors such as voltage rating, breaking capacity, service conditions, and installation environment all play crucial roles in determining the most suitable VCB for specific applications. Thus, this article will guide you through seven essential tips to effectively navigate the selection process for Vacuum Circuit Breakers, helping you make informed decisions that enhance the performance and longevity of your electrical systems.

Understanding the Purpose and Functionality of Vacuum Circuit Breakers

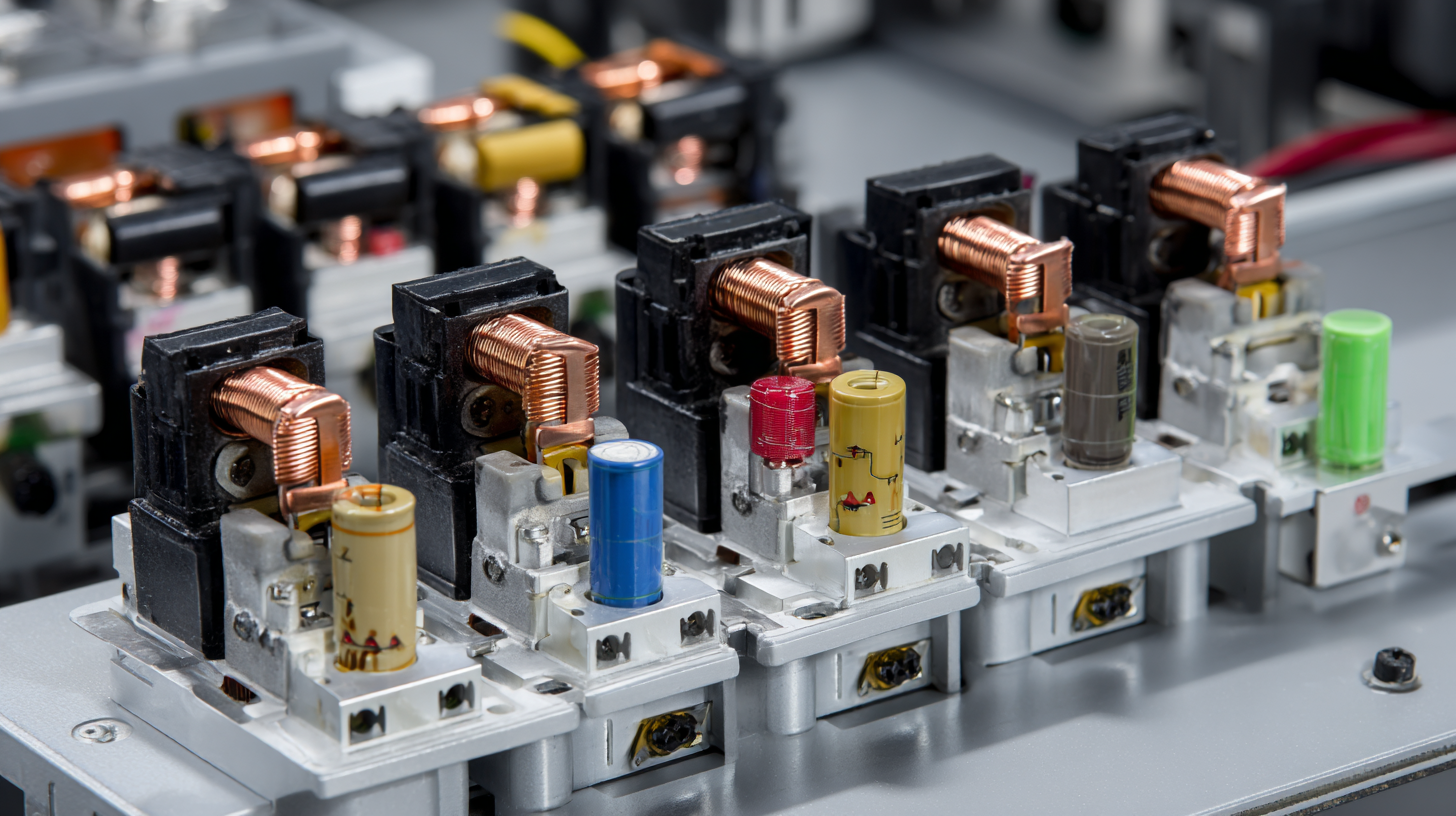

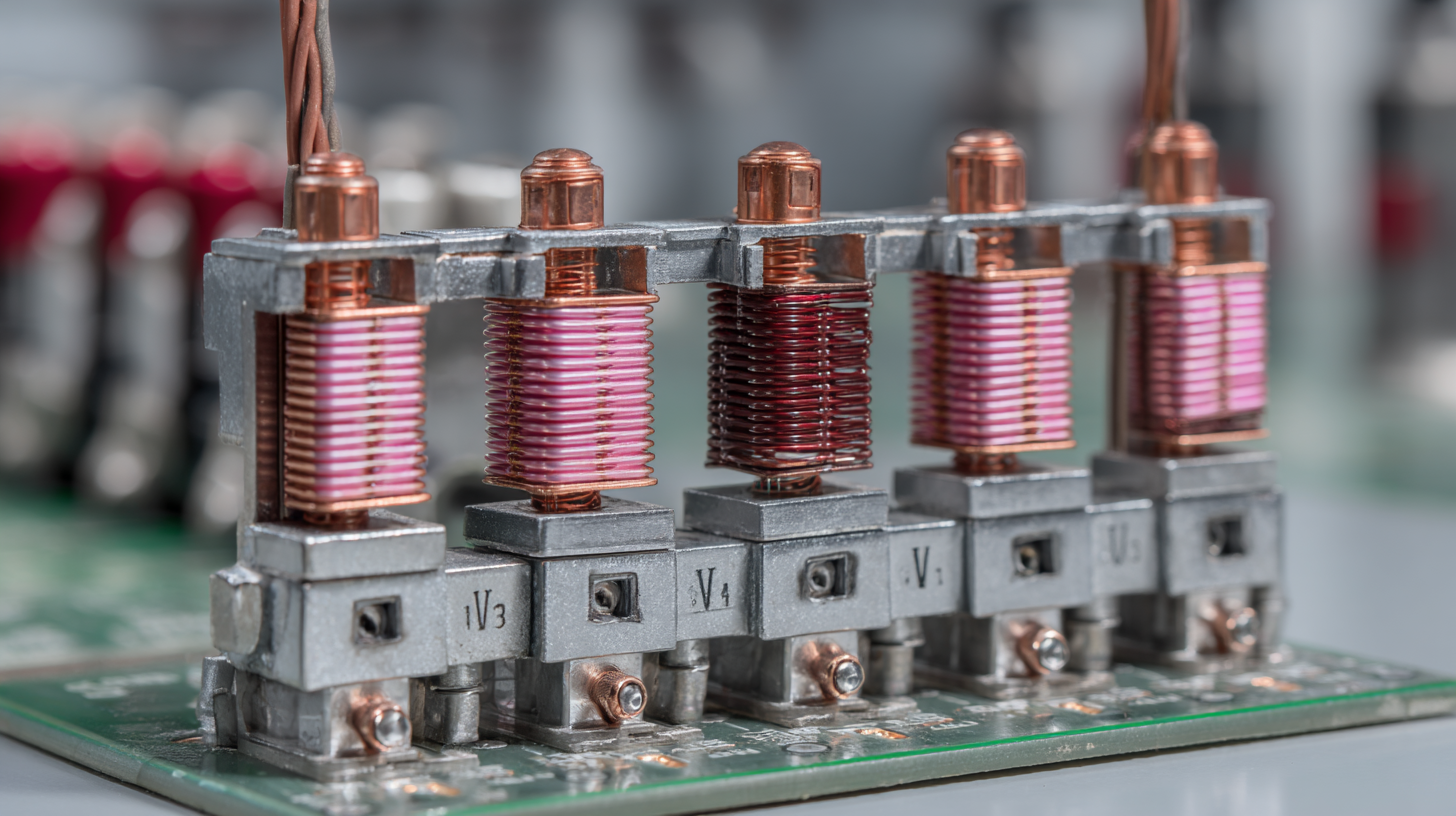

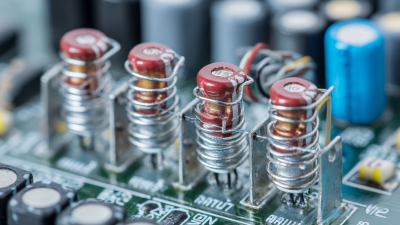

Vacuum circuit breakers (VCBs) play a crucial role in modern power systems, utilizing advanced vacuum switching technology that has evolved significantly over nearly a century. Their primary purpose is to interrupt electrical circuits during faults, ensuring the protection of electrical networks and equipment. Recent innovations have seen the development of eco-friendly VCBs that utilize clean air instead of harmful gases, showcasing a commitment to sustainable practices in energy management.

As the industry moves towards greener solutions, the introduction of products like the 145kV vacuum circuit breakers reflects a growing trend towards eliminating sulphur hexafluoride (SF6) in favor of more environmentally friendly technologies. With the global market for vacuum circuit breakers projected to grow at a robust rate, it emphasizes not only the demand for reliable power protection solutions but also the importance of innovation and partnerships in driving this transformation. The ongoing advancements in VCB technology signify a shift towards safer, cleaner, and more efficient power systems, highlighting their critical functionality in the evolving energy landscape.

7 Essential Tips for Choosing the Right Vacuum Circuit Breaker - Understanding the Purpose and Functionality of Vacuum Circuit Breakers

| Tip | Description | Considerations |

|---|---|---|

| 1. Understand the Specifications | Familiarize yourself with the voltage, current ratings, and interrupting capacity of the circuit breaker. | Ensure it matches your application's electrical requirements. |

| 2. Choose the Right Protection Level | Select a circuit breaker that provides adequate protection against overloads and short circuits. | Evaluate the sensitivity and response time of the breaker. |

| 3. Assess Operating Conditions | Consider the environmental factors where the breaker will be installed. | Check for temperature variations, humidity, and potential contaminants. |

| 4. Review Maintenance Requirements | Know how often the breaker needs to be tested and maintained. | Plan for ease of access during maintenance intervals. |

| 5. Evaluate Circuit Breaker Types | There are different types of vacuum circuit breakers, each suited for specific applications. | Determine which type aligns with your needs and operational environment. |

| 6. Confirm Compliance with Standards | Ensure the circuit breaker complies with relevant industry standards and certifications. | Check for international safety and performance standards. |

| 7. Seek Expert Advice | Consult with professionals who have experience with vacuum circuit breakers. | They can provide insights tailored to your specific requirements. |

Key Factors to Consider When Selecting Vacuum Circuit Breakers

When selecting the right vacuum circuit breaker (VCB), there are several key factors that must be taken into account. First and foremost, understanding the voltage requirements is crucial. According to the International Electrotechnical Commission (IEC), VCBs are typically suitable for medium voltage applications, ranging from 1 kV to 38 kV. Ensuring compatibility with your specific voltage range is vital for optimal performance and safety.

Another critical factor is the rated breaking capacity, which indicates the maximum current a circuit breaker can interrupt without damage. Industry reports suggest that VCBs can have breaking capacities that range from 10 kA to over 50 kA depending on the application. Additionally, consider the operational environment where the VCB will be installed. Factors such as potential exposure to dust, moisture, or extreme temperatures can influence the selection process. Furthermore, maintenance requirements should not be overlooked; VCBs typically offer low maintenance needs due to their sealed design, thus enhancing their reliability in various applications. Making informed decisions based on these parameters can significantly enhance system safety and performance.

Evaluating the Voltage and Current Ratings for Your Application

When choosing the right vacuum circuit breaker (VCB) for your application, evaluating the voltage and current ratings is crucial. The voltage rating determines the maximum voltage the circuit breaker can handle without failing, while the current rating indicates the amount of electrical current it can safely interrupt. It's essential to select a VCB that matches or exceeds the operational conditions of your system to ensure safety and reliability.

One essential tip is to assess the specific voltage levels your equipment operates at. Common voltage ratings for VCBs include low voltage (up to 1 kV), medium voltage (1-36 kV), and high voltage (above 36 kV). Depending on your application, choosing a circuit breaker with a voltage rating slightly higher than your maximum operating voltage can provide an additional safety margin.

Another important factor is the current rating. Consider both the continuous current that your equipment will draw and the potential fault currents that could occur during short circuits. Selecting a vacuum circuit breaker with a current rating that accommodates these variables ensures that the breaker will effectively protect your electrical system under varying conditions. Always consult technical specifications and manufacturers guidelines to make well-informed decisions regarding both voltage and current ratings.

Voltage and Current Ratings for Vacuum Circuit Breakers

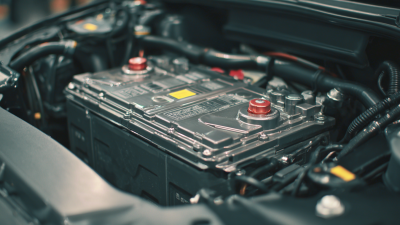

Assessing the Environmental Conditions and Installation Requirements

When selecting a vacuum circuit breaker (VCB), it is crucial to assess the environmental conditions where it will be installed. Factors such as temperature, humidity, and exposure to dust or corrosive elements can significantly impact the performance and longevity of the breaker. For instance, areas with high humidity may require breakers with enhanced insulation and sealing features to prevent moisture ingress that can lead to failures. Similarly, in environments with extreme temperatures, it is essential to choose breakers designed to operate efficiently within the specified range to ensure reliable protection.

Installation requirements also play a pivotal role in the selection process. Understanding the spatial constraints and layout of the installation site is necessary to determine the appropriate breaker size and type. Additionally, the power system characteristics, such as fault levels and operational frequency, must align with the specifications of the chosen VCB. It is vital to consult installation guidelines and, if needed, collaborate with manufacturers to ensure that all regional regulations and safety standards are met, thus facilitating a smooth installation process while optimizing operational efficiency.

Comparing Manufacturer Reliability and Product Support Services

When selecting a vacuum circuit breaker (VCB), evaluating manufacturer reliability and product support services is critical. A recent report by Research and Markets indicates that the global vacuum circuit breaker market is projected to grow at a CAGR of 6.2% from 2023 to 2030, highlighting the increasing demand for reliable electrical infrastructure. This trend underscores the importance of choosing manufacturers with a proven history of reliability and performance in their products. Manufacturers with quality certifications, such as ISO 9001, are often more likely to deliver dependable equipment, which directly impacts the operational efficiency and safety of electrical systems.

Additionally, robust product support services are essential for ensuring long-term reliability. According to a survey conducted by TechValidate, 72% of companies reported that reliable after-sales support significantly influenced their purchasing decisions. A manufacturer that offers comprehensive training, prompt technical assistance, and availability of spare parts enhances user confidence in the product. Features such as extended warranties or maintenance contracts can also serve as indicators of a manufacturer's commitment to customer satisfaction and product longevity. Investing in a VCB from a manufacturer that prioritizes product support can lead to lower total costs of ownership and improved system reliability.

Related Posts

-

Energy Storage Battery Innovations Projected Growth Trends at 2025 China Import and Export Fair

-

7 Reasons Why the Lithium Iron Phosphate Battery is the Best Choice for Your Energy Needs

-

Diving into Best Battery Storage Issues That Global Buyers Must Address

-

5 Essential Tips for Maximizing Your Energy Storage Lifep04 Battery Performance

-

Finding the Ideal Manufacturer for Your Best Low-Speed Vehicle Battery Needs

-

Understanding the Functionality of a Latching Relay in Modern Applications